Heart valve device investigation laboratory

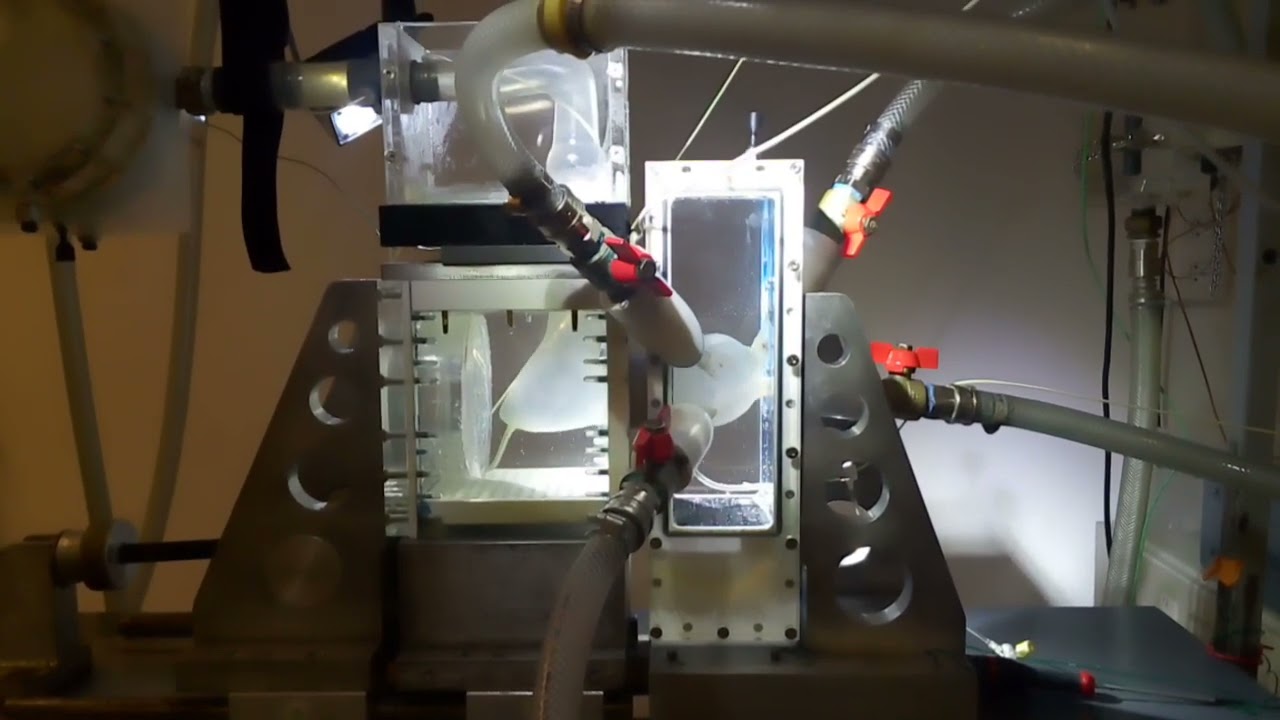

The new in vitro/in silico laboratory for translational research on valvular heart disease has a state-of-the-art cardiac simulator. This simulator includes anatomical models of the left atrium and ventricle, capable of producing contractions independently, in order to obtain physiological and/or pathological flow conditions (heart rate, flow, pressure). A fluid of the same viscosity as blood is set in motion by the complementary actions of contractions of the atrial and ventricular cavities, and the opening and closing movements of the aortic and mitral valve prostheses. The platform includes both clinical (via echocardiography) and fluid mechanics (via electromagnetic flow meter, pressure sensors) data acquisition materials.

The cardiac simulator allows the investigation, validation and optimization of the structural and functional performance of the valve devices under normalized, reproducible and controlled physiological and pathological conditions.

Under the direction of Dr. Philippe Pibarot, Director of the valvular heart disease research group and Director of cardiology research, the in vitro laboratory is operated by passionate and highly qualified professionals. Experienced engineers perform all in vitro tests as well as in silico analyses. All experiments are supervised by a team of experts from the Institute’s multidisciplinary cardiology department.

Facilities & Services

The in vitro/in silico platform includes:

- An anatomical silicone replica of the left heart with viscoelastic characteristics close to physiological reality (left ventricle, left atrium and aorta);

- Devices that reproduce the resistance and compliance of the systemic network;

- Two plunger pump who allows the ventricular and left atrium to be controlled;

- An electronic flowmeter for measuring the valve flow rate;

- Piezoelectric pressure sensors (catheter) to measure pressures in the heart chambers and in the aorta;

- A clinical cardiovascular ultrasound system for speed measurements in continuous, pulsed and flow Doppler mode;

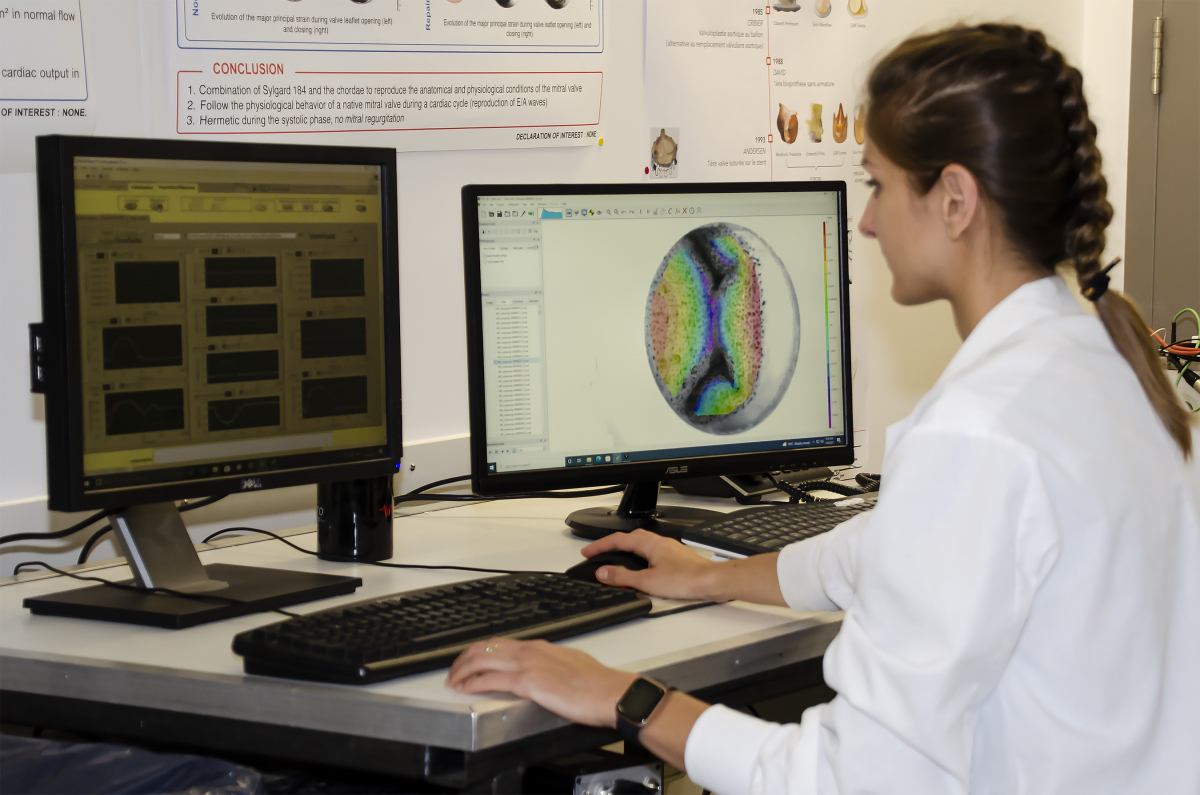

- Two high-speed cameras for 2D and 3D analyses of the kinetics and deformation of the leaflets;

- A 3D printer (multi-material) to manufacture a wide variety of valves and cardiac chambers normal and pathological.

Our expertise and services offered:

- Hemodynamic measurements:

- Echocardiography (speed, transvalvular pressure, effective valve area…);

- Transvalvular flow rates and pressures.

- Measurements using the high-speed camera:

- Geometric orifice area (GOA) – valve planimetry as a function of time;

- “Pin wheeling index” – calcul of localized deformations of the free edge of the leaflet when closing.

- Measurement using two high-speed cameras:

- Displacement and deformation of the valve leaflets during the cardiac cycle using the system of stereometry and image correlation.

Request for services

To obtain an estimate of the costs of your project and request services, complete the service request form.

For further information, please contact: